Ruhrstahl/Kramer X-4

In early 1943, work

began on the X-4 air-to-air wire-guided missile by Dr. Kramer at Ruhrstahl.

The missile received a development order in the summer of 1943 and was

given the number 8-344 by the RLM, and was developed to give fighters a  chance

to down the ever increasing number of Allied bombers from outside of their

defensive gun range.

chance

to down the ever increasing number of Allied bombers from outside of their

defensive gun range.

The X-4 featured

a tapering, cigar-shaped fuselage, with four small swept wings and four

smaller tail fins. At the ends of two of the opposing wings were small

pods which held the wires that unwound during the X-4's flight. On the

wing tips of the other two main wings were simple flares to aid the pilot

in keeping the X-4 on it's intended path. The tail unit contained small

spoilers which could control the missiles pitch and yaw. Power was supplied

by the BMW 109-548 rocket engine. The fuel was held in a cleverly designed

spiral fuel tank (to save space). A piston was fitted into each coiled

fuel tank, and the fuel was pushed into the combustion chamber at the rear

of the missile by discharging compressed air to force the piston against

the fuel. The two fuels (R-Stoff or Tonka and SV-Stoff or Salbei) were

hypergolic, which means they ignited upon contact with each other. A warhead

weighing 20 kg (44.1 lbs) with a destructive blast radius of 7.6 meters

(25 feet) was mounted in the nose of the missile, being detonated by the

pilot, impact or by an acoustical proximity fuse, tuned to the pitch of

the bomber's propellers.

A typical flight

would have the carrier aircraft reaching the same altitude or slightly

higher than the target. The X-4 would be released from the ETC 70 or 71

bomb rack, and would spin at approximately one revolution per second (this

was achieved by having the wings slightly offset from the missile center

line), the gyro being used mainly for line of flight only. The pilot

can then steer the missile (FuG 510/238 "Düsseldorf/Detmold" system)

by the use of a small joystick in the cockpit. Seven seconds after launching,

the acoustic proximity and impact fuses are armed. A self-destruction fuse

is also actuated about 30 seconds after launch. The Kranich acoustical

fuse (tuned to the pitch of the bombers propellers) would activate the

firing mechanism within 40 meters (131 feet), with an additional slight

delay allowed for the distance to close to within five meters (16 feet)

before detonation of the warhead. A maximum speed of 1152 km/h (716 mph)

could be reached; the range of attack was to be between 1.5 km and 3.5

km (.93 mile and 2.2 miles), although there was 5.5 km (3.4 miles) of wire

on the spools.

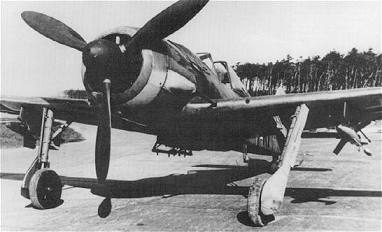

By August 1944,

225 prototype X-4s had been completed, with the first air launched test

occurring on August 11, 1944 by an Fw 190. Tests continued through early

February 1945, also by Ju 88s. Test flights were also undertaken by a Me

262 jet fighter with two X-4 missiles under the wings outboard of the jet

nacelle, but were not launched.

The production

of the X-4 was simple, the fuselage being made up in three sections; a

turned steel nose which contained the warhead, a cast aluminum center section

and a tail section made from sheet aluminum. The design of the missile

was set up so that unskilled labor could assemble

the missiles, indeed, the sheet metal sections assembled by tabs in

one section being pushed into slots of another section. The plywood wings

were secured to the missile's center section with simple nuts and bolts.

Approximately 1000-1300 airframes had been finished at Ruhrstahl's Brackwede

factory by early 1945, and were awaiting their rocket motors, when the

BMW facility at Stargard was bombed, destroying all the finished BMW 109-548

rocket engines. This missile was intended to be issued in numbers to the

Luftwaffe by the early Spring of 1945, but the bombing of the BMW rocket

engine factory, and the war's end prevented the combat use of the world's

first guided air-to-air missile.

Ruhrstahl/Kramer X-4 Dimensions

Span

(across wings) |

Length |

Height

(across wings) |

Max Diameter

(fuselage) |

.575 m

1' 11" |

1.907 m

6' 3" |

.575 m

1' 11" |

.222 m

8.75" |

Ruhrstahl/Kramer X-4 Weights

| Operational |

R-Stoff |

RV-Stoff |

Warhead |

Engine |

Wings |

Bobbin & Wire |

Battery |

Gyro & Relays |

60 kg

132 lbs |

1.7 kg

3.75 lbs |

6.3 kg

13.9 lbs |

20 kg

44 lbs |

25 kg

55.1 lbs |

1.5 kg

3.3 lbs |

5 kg

11 lbs |

1 kg

2.2 lbs |

1.5 kg

3.3 lbs |

Ruhrstahl/Kramer X-4 Performance

| Max Speed |

Thrust |

Duration |

Acceleration |

Max Range |

Glide Ratio |

1152 km/h @ 6500 meters

716 mph @ 21325' |

1600 kg |

33 sec. |

3.5 G |

5.5 km

3.4 miles |

1:5 - 1:6 |

Ruhrstahl/Kramer X-4

Models

| Manufacturer |

Scale |

Material |

Notes |

| Airmodel |

1/72 |

Resin |

w/launch racks, included in Luftwaffe Weapons Set # 1 |

| DML/Dragon |

1/72 |

Injected |

w/launch racks, included in Me P.1101 kit |

| RS |

1/72 |

Resin |

included in BV Ae 607 & Me P.1106 |

| Resin Master |

1/72 |

Resin |

w/launch racks |

| Trimaster |

1/48 |

Injected |

w/launch racks, seperate acoustic or impact noses,

included in Fw 190F-8 kit |

Assembly Procedure of the 8-344

(X-4) air-to-air wire-guided missile

Assembly Procedure of the 8-344

(X-4) air-to-air wire-guided missile

Left: The Kranich Acoustical Fuse.

The Plastic Diaphragm is centered in the missile, and is connected by

means of a lever arrangement to a needle-like pointer whose mass is much

smaller than that of the diaphragm. Two opposing openings (covered by a

fine mesh screen) in the missiles body allow sound to enter to the diaphragm,

and when the missile passes through the the transition region of the Doppler

frequency shift, the vibrations of the diaphragm excite resonances in the

needle, the needle touches an electric contact, completes the circuit and

fires the igniter.

Note: the X-4 could be fired at

targets up to 56° away

Abwurfbereich = Release Range

H - 6000 m = Height of 19685

feet

Vo - 180 m/s = Starting Speed

of

648 km/h (402 mph)

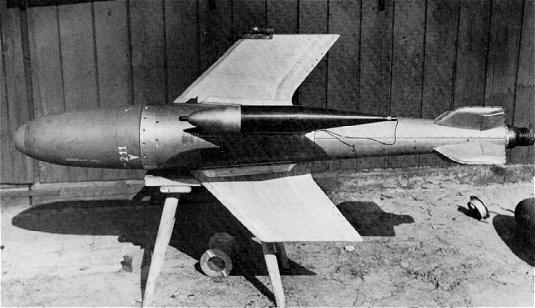

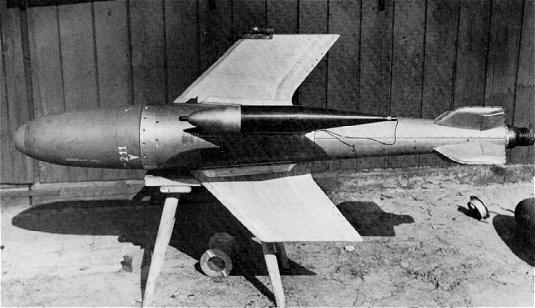

A wartime photo of the Ruhrstahr/Kramer 8-344 (X-4)

X-4 Details

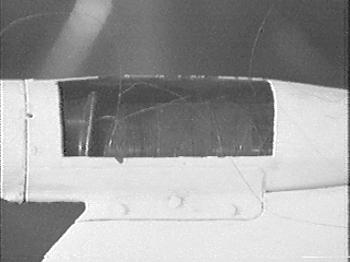

A wingtip bobbin is exposed, revealing the wire

spool

|

One of the coiled fuel tanks, split open to see

the piston

|

| A US soldier examines the rear housing of an X-4

|

X-4 center sections (complete w/BMW 548 rocket

engines)

found at the Hovelhofer facility

|

More

component close-up photos from Ray Corridon's webpage

Three stills from a filmed rocket engine bench test

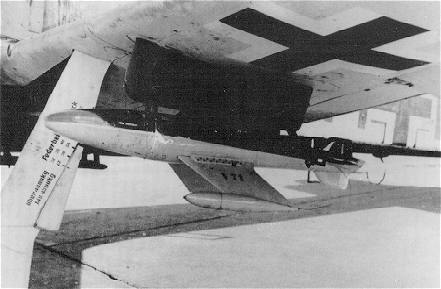

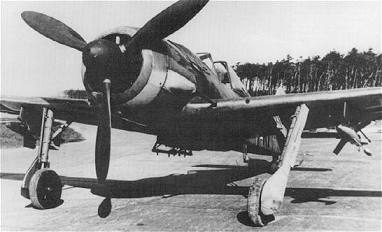

Fw 190A-8, November 1944, during testing

|

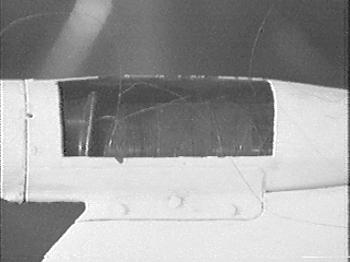

A closeup photo of the small joystick used

to control the X-4 in flight. An elbow rest was

also provided for the pilot on the starboard side

of the cockpit to allow better control and comfort

while guiding the X-4. |

|

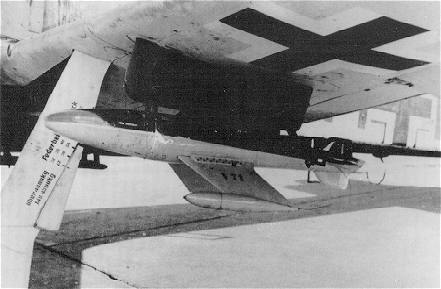

The X-4 mounted under a Ju 88 during tests at Karlshagen,

August 1944

The X-4 is released, the rocket fires and disappears

in the distance in these stills from a filmed test launch

The X-4 is released, the rocket fires and disappears

in the distance in these stills from a filmed test launch

The X-4 Today

Cosford Royal Air Force Museum in Shropshire, England

Photo by Graham Causer, May 1998

|

NASM Paul E. Garber Facility

Photo by Dan Johnson, 1993

|

Cosford Aerospace Museum, Shropshire, Great Britain

Photo by Matthew Hopson, June 1985

|

U.S. Airforce Museum, Dayton, Ohio, USA

Photo by Rick Geithmann

|

chance

to down the ever increasing number of Allied bombers from outside of their

defensive gun range.

chance

to down the ever increasing number of Allied bombers from outside of their

defensive gun range.